Safety & Security

Growing concerns regarding natural and manmade disasters clearly illustrate the importance of glass safety and security. If glazing shatters during an extreme weather event or earthquake a secondary disaster is often created from scattering and falling glass shards.

Lintec's window films minimize the risk of personal and property damage caused by glass fracture during an earthquake or other disaster, thereby greatly contributing to the building's overall safety.

Shatterproof Measures

The superior properties of WINCOS Architectural Films preventing the scattering of glass shards is demonstrated via a variety of tests including distortion*, impact and explosion, etc. These tests clearly validate the shatterproof capability of the films.

- ●Test 1: Distortion

-

Test method: An experimental observation of frame displacement. The simulated earthquake test uses a "fixed sash window" to observe whether the test specimen scatters or not after a fracture. This test was conducted by the Building Research Institute under the control of the Ministry of Land, Infrastructure, Transport and Tourism in Japan as a trustee.

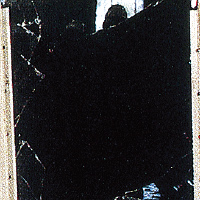

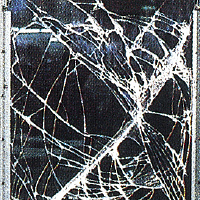

Result: In the case of conventional float glass, sharp shards scattered as far as 15m away. In the case of glass with WINCOS 1501UH applied, fine cracks were evident and some glass powder was scattered but otherwise the scattering of shards was minimal.

Download the specification sheet for our Safety Window Films along with their Physical Properties information.

Float glass

Float glass Glass with WINCOS 1501UH applied

Glass with WINCOS 1501UH applied

- ●Test 2: Impact

-

Test method:An impulse fracture test according to ANSI standards (US safety glazing standards), conducted at the Department of Industrial Design, Faculty of Engineering, Chiba University.

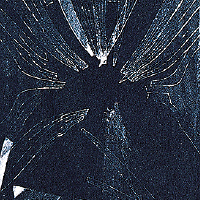

Result: In the case of float glass, the test specimen broke at the impact point, scattering large sharp shards. In the case of glass with LUMICOOL 1501UH applied, the impact point did not collapse.

Float glass

Float glass Glass with WINCOS 1501UH applied

Glass with WINCOS 1501UH applied

- ●Test 3: Explosion

-

Test method: An experimental observation of the scattering of float glass caused by a blast from an explosion conducted at the National Chemical Laboratory for Industry, Agency of Industrial Science and Technology, Ministry of International Trade and Industry (currently the National Institute of Advanced Industrial Science and Technology).

Result: The scattering of glass from a test specimen with a size of 60cm by 60cm caused by a blast from an explosion of No.3 Kiri Dynamite 1.2m away was examined.

The 6mm thick float glass was fractured at a blast pressure of about 1.5kg/cm2, the area of scattering extending to more than 60%.

The glass affixed with WINCOS 1501UH remained shatter-resistant against a blast pressure of up to approximately 4.2kg/cm2, comparable to 6.8mm thick wire glass. Float glass

Float glass

(300g explosive) Glass with WINCOS 1501UH applied

Glass with WINCOS 1501UH applied

(400g explosive)

Our extensive achievements, which are backed up with over 20 years' experience, reinforce the superior reliability of our products.

Building on the effects of the 1978 Miyagi earthquake, Lintec's efforts have been focused on establishing the shatterproof capabilities of window films applied to glazing. We have been making continual efforts to pursue the advancement of window film safety. For example, Lintec conducted interlayer displacement tests, which examine the scattering of glass resulting from "distortion" which would be anticipated during an earthquake. This was the first test of its kind in Japan, and took part in the establishment of relevant JIS standards through the accumulation of quantitative experimental evaluation. These long-term efforts over many years back up the high reliability of our products.

Crime Prevention Measures

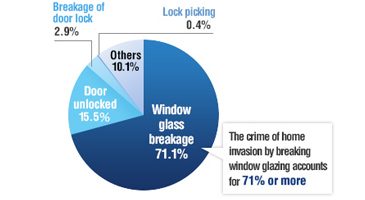

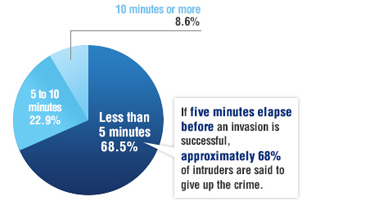

In recent years the crime of home burglary has grown and the invasion tricks employed are becoming increasingly malicious and diverse.

When the clear shatterproof type 1561UH window film, which is the most suitable for crime prevention, is applied to the entire surface of the glazing it can substantially retard the breaking and the penetration of window glass, thereby resulting in a substantial contribution to crime prevention in buildings.

Metropolitan Police Department

web site: "Living full of security"

(300g explosive)

Japan Urban Security Research

Institute (JUSRI report)

(400g explosive)

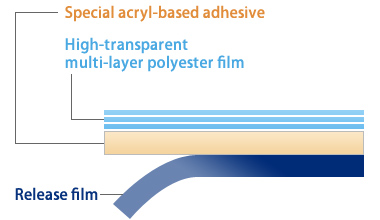

The 1561UH window film features a three-layer structure (film thickness of 395µm and total thickness of 425µm) in which our unique coating and laminating technology allows the lamination of high transparency PET film. The transparency of the film is comparable to conventional glass scattering prevention film (film thickness of 50µm and total thickness of 80µm) and the tensile strength of the film is more than six times that of conventional film.

- ●Test 1: Testing the fracture of a crescent sash lock through simulating breakage by prying (in-house evaluation)

-

Test method: Measurement of time before successfully "breakage by prying" the crescent sash lock with a secondary lock.

Tools used: Screwdriver and cutterResult: More than five minutes were needed before successful glass breakage and invasion.

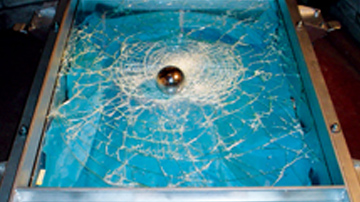

- ●Test 2: Multiple drop tests simulating breaking by striking

-

Test method: In accordance with the EN356 standard.

Steel ball used: 100mm in diameter, weighing approximately 4.11kg.

Method of dropping the steel ball: The steel ball was dropped toward around the center, to each vertex of an equilateral triangle with a side length of 130mm.

Size of test specimen: 900 mm by 1100mm.Result: No penetration through the glass was observed after dropping the steel ball from a height of 1,500 mm and 3,000 mm three times in succession.

When applying the film the sash should enclose the film within the frame perimeter.

Product Construction